Recycling center opens state-of-the-art facility after devastating fire – York Dispatch

PostedIt was a hard blow to take when last March when a fire swept through Penn Waste’s Manchester Township recycling center.

“One of the devastating things for me was seeing the employees in the parking lot during the fire. They took it really hard,” said Shawn Querry, Penn Waste’s recycling center site manager. “We have people that want to be here. That was devastating to see that.”

Just over a year later, however, the company has launched a new — and decidedly more high tech — facility that’s able to process some 420 tons of recyclables per day.

“To be back up and be bigger and better is amazing to me,” Querry said. “The employees put a lot of work into it and take pride in what they do.”

It took $35 million to get the facility back up and running, but what Penn Waste got in return was a state-of-the-art facility with a fire suppression system to keep history from repeating.

“We initially projected the rebuild to take over a year and a half due to parts delays and the complexity of the rebuild,” Penn Waste spokesperson Amanda Moley said. “We were fortunate to have several vendors who all worked together to get us back up and running in record time.”

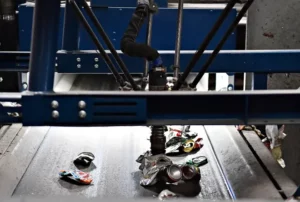

Automation is even more prevalent at the plant. Before the fire, the facility had six robotic sorters to take out things that could not be recycled or processed through the system.

Now, there are 11 robots to help in the sorting.

“We were able to change things up with optical sorters and robots,” Querry said, “and take the risk out of it for employees where employees are sorting through recyclables. We struggled with things that shouldn’t be put into a recycle bin.”

Automation also makes things more efficient.

The facility takes in 420 tons of recyclables a day and processes 48 tons of it an hour. Before the fire, the facility was processing 40 tons an hour.

“We have the capability to run 50 tons an hour, but we don’t need to right now,” Querry said.

Taking out things that could not be recycled also became more efficient, going from 30 picks a minute to a thousand picks a minute. It also takes less manpower. Before the fire, the recycling center had 21 human sorters. After the fire, that number was reduced to seven.

With automation came a reduction in the number of people needed to operate the recycling center. The workforce now stands at 25, from a high of 67 and the workday has been reduced to one 12-hour shift.

“Not all the material we were getting pre-fire came back to us after fire,” Querry said. “We just didn’t have the volume for a two-shift operation as of right now.”

Employees who were replaced by the robotic sorters were given the opportunity to shift to Penn Waste’s hauling division, if they were physically capable of doing the job.

“Some of the folks did that. The folks that didn’t take that opportunity unfortunately were laid off,” Querry said. “We brought back who we needed to bring back.”

Besides the obvious dangers of handling large volumes of recyclables, such as glass shards or sharp metal pieces, is the threat that comes from rechargeable batteries being tossed out into the recycling bin. The fire that broke out on March 8, 2022, was thought to have been caused by a rechargeable battery.

“Due to how fast the fire happened and how hard it was to put out, the fire department believes it was a rechargeable battery that caused the fire,” Moley said.

It was around 8:30 p.m. when the fire broke out in the middle of the facility’s cardboard bunker, Querry said.

“We had 40 employees on site, and they tried to put the fire out and they couldn’t because it got too hot,” he said.

The place went up in flames in about 10 minutes, Querry said, because nothing could be done to put it out. Damage to the metal building was minimal, but the machinery used to sort the recyclables was rendered unusable due to smoke and water damage.

Querry said they were able to get machinery that processed glass and cardboard up and running about five weeks after the fire. The rest of the recyclable material was taken to a sister facility in Virginia while plans were developed to retrofit the building with new technology. Starting in January, the facility was shut down for two months to install the new processing technology.

Changes made post-fire now can nip fire threats in the bud, Moley said.

One of them was the installation of Fire Rover, which is a fire detection technology and fire suppression system.

“It uses thermal imaging and 24/7 monitoring to notify us of any fires starting that we do not see ourselves,” Moley said. “We’ve also added foam fire suppression units throughout the building and near our holding bunkers. Our employees also go through special training so they are prepared should we experience another fire.”

All in all, what has resulted after what was a dark time last year is a more efficient and safer recycling center for York County.

“The technology in the waste industry today is amazing,” Querry said. “We’ve worked with our vendors to automate. Who would’ve thought in recycling we would be able to automate the plant.”